Newsletter

January 2024

Tip

Maintaining stock accurately is critical for the planning of material. Companies count stock physically to cross check physical stock with the stock in the software.

Most of them try to count full stock in one go. For this, sometimes the operations have to be stopped while the stock check is going on.

A better way is to randomly check a few items everyday. It is called the Perpetual Stock Check. Since the items are fewer, the counting is accurate.

Also, costlier 'A' category items can be counted more frequently as compared to lower value items.

Did you know?

In OurSys, it is possible to set a minimum order quantity (MOQ) for a given customer.

Once MOQ is set, OurSys will warn whenever the sales order quantity is less than the MOQ quantity.

This facility is switched off by default as a safety measure. You may request us to switch it on if required.

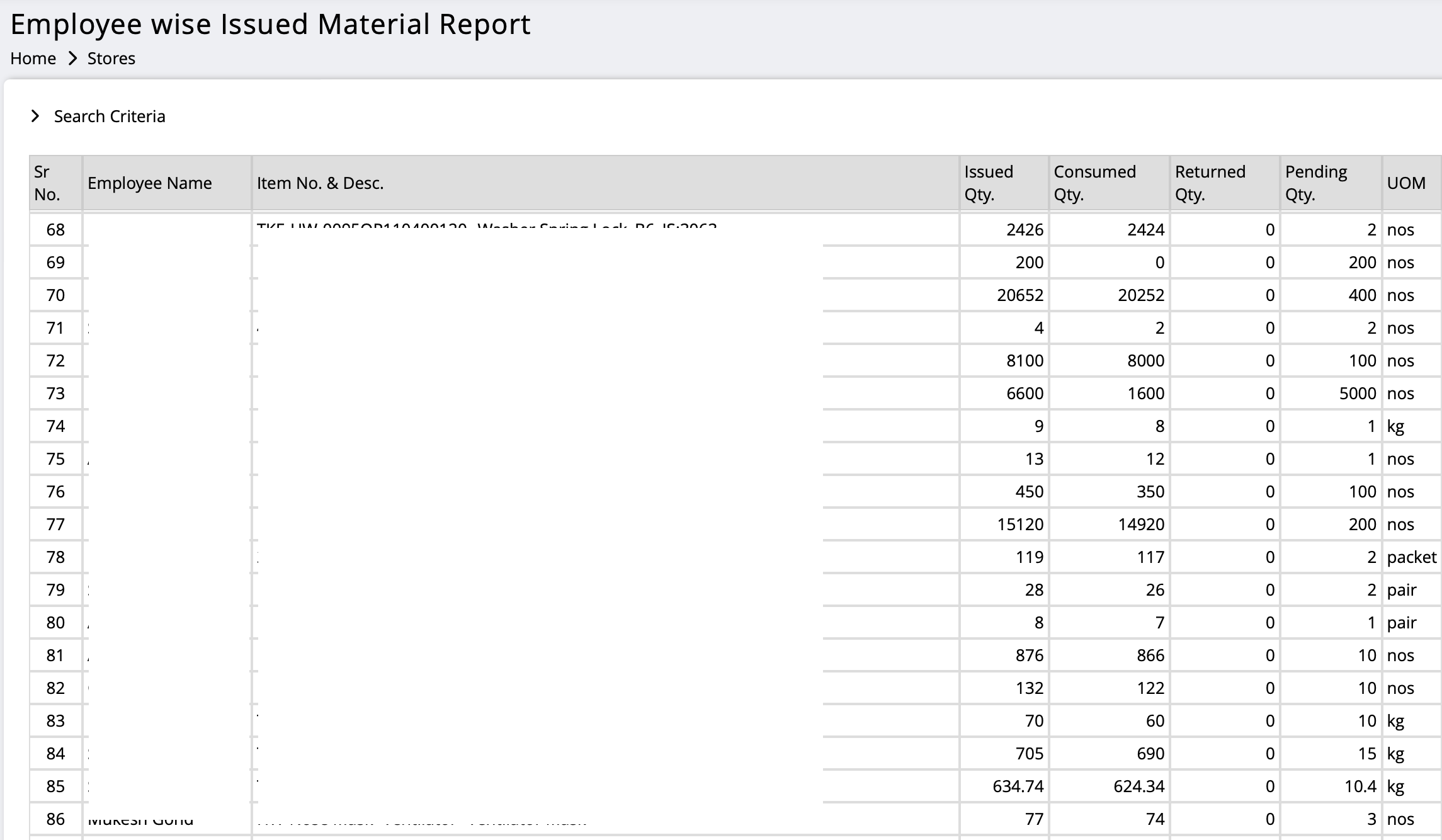

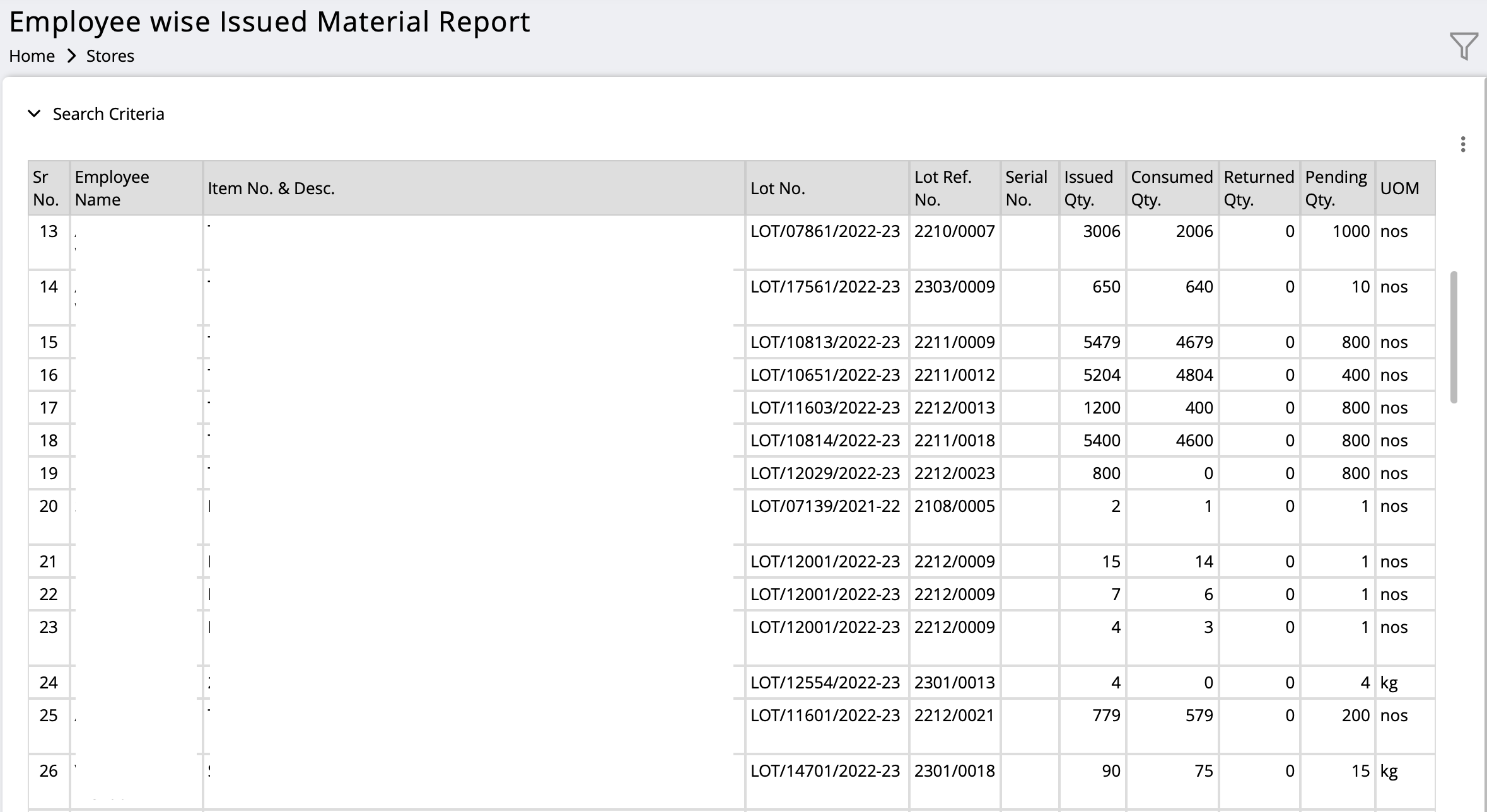

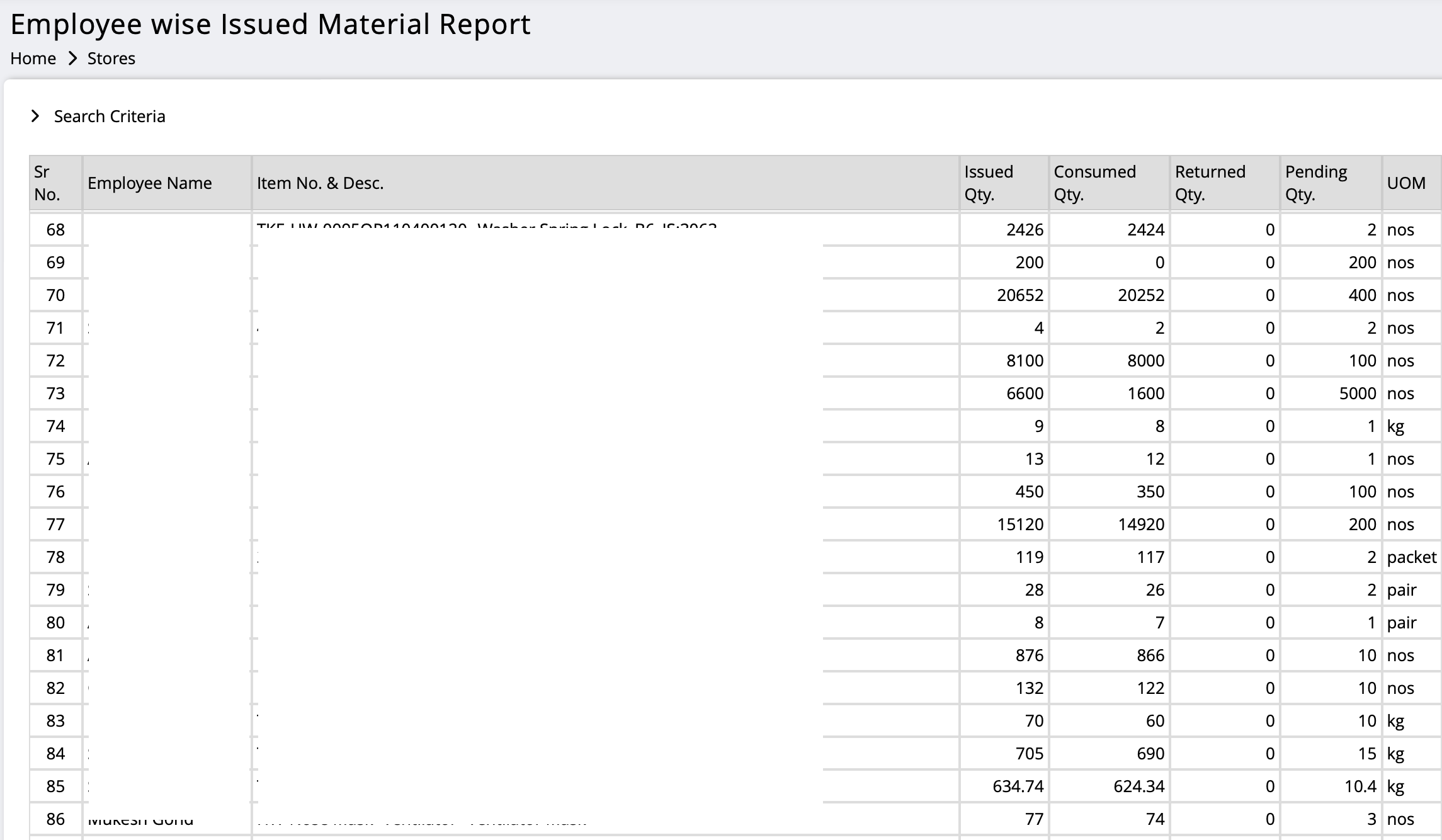

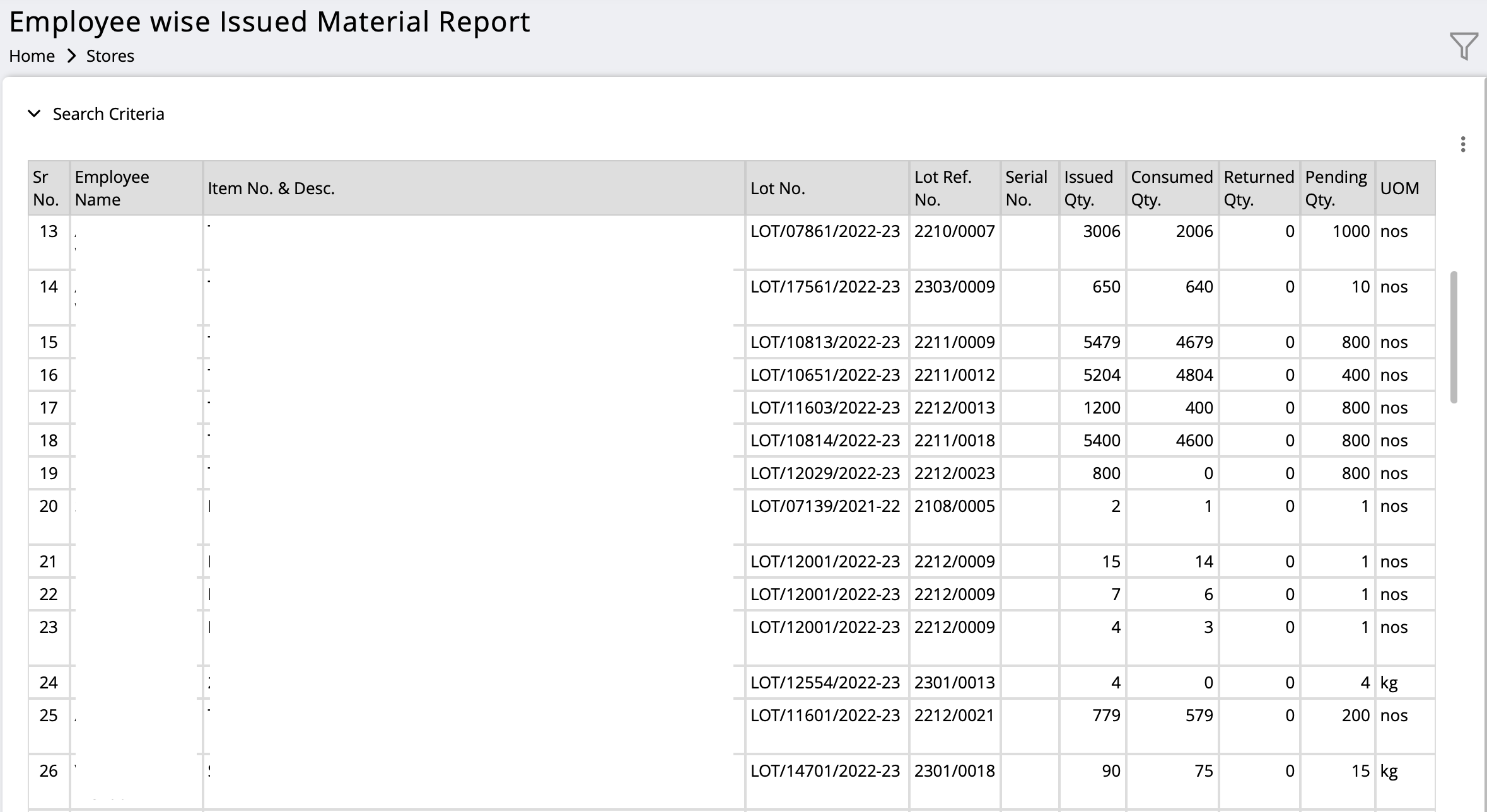

Understanding Reports

| Report Name |

Employee wise Issued Material Report |

| Where to find it |

Under Stores under the Reports section |

| Who should use this |

Stores & Production head |

| What frequency to check: |

As and when required |

| Filters for the report |

Item, Item Category, Employee are some of the filters. |

Screenshot of the Report

This report can be viewed Lot wise / Serial No as well.

Information in the report & how to use it:

-

Whenever any returnable material such as tools, cutting tools etc are issued, the name of the person to whom it has been issued is captured.

This report shows the names of the people with whom such material is lying.

-

This helps you to keep track of the material and followup to get it back.

Notification

- We are happy to inform you that we have shifted our office to a more organised & convenient place in the same vicinity. We invite you to visit and grace our office.

What's new

-

History Card for Gauges & Instruments Introduced

OurSys has now introduced History Cards for all measuring instruments and gauges. This will help to meet compliance requirements easily and quickly.

Shortcut to transactions added to Stock Ledger

Users can now go to the related transaction straight from the stock ledger. This helps to audit and investigate further about the transaction.

Stock Valuation Report Enhanced

We have now provided a provision to include or exclude value of in-transit stock between company locations.

Daily Production capturing enhanced

Users can quickly enter daily production entries for multiple job orders in one go for a selected process.

Article

An article on 'Purchase Best Practices'

Purchasing is a critical process and depending upon how it is done it can affect margins drastically. Here is a list of Best Practices for Purchase.

Read the full article

Case Study

On maintaining status of Drawing Approval by customers

Customer Introduction:

An engineering company requiring drawing approval from the customers for production clearance.

Problem / Goal:

Orders received from customers typically come with a Late-Delivery Clause. The delivery dates are defined in the order assuming a certain period for drawing approval activity.

But due to some reason the customer delays the approval, the manufacturing starts late and thus there is a danger of being penalised under the LD clause.

In such cases, it is required to furnish details of communication in order to prove that the delay was due to customers delay in approving drawings.

Without a proper system, it is a tedious task to produce this evidence.

The Solution:

We developed a feature to record various stages of drawing approval along with the dates.

The Result / Benefits:

Thus it became easy to retrieve all the relevant dates and references to customer emails / communication in order to furnish the evidence of delay from customer end.

Let us know if this feature could be useful to you. We will enable the setting for you.

Feedback

The intention of this newsletter is to make our customers aware of the features of OurSys and help them to utilise OurSys to the fullest. We would like to have your feedback on how we can further improve this effort.

Please click here to give us your feedback.